Time to ditch the ‘fast kitchen’ – carbon footprint equals heating a home for a year

A new kitchen could be as polluting as flying from London to Portugal and back, heating the average home for a year or eight years of daily Starbucks.

Over the past 5 months, HØLTE has conducted extensive research to understand the full carbon footprint of all of their products – revealing pretty shocking findings.

When people buy a house, one of the first jobs on their list is usually to rip out and replace the kitchen. For companies like Hackney-based kitchen design studio HØLTE, that’s ostensibly a good thing – after all, their business depends on people’s desire to put their own stamp on their space. But our ‘fast-kitchen’ habit is taking a savage toll on the planet as the climate cost of newly fitted units can be staggering.

Keen to understand the full impact of their industry on the environment, small business owners and HØLTE founders Fiona and Tom Ginnett decided to look deep into the data and determine the full carbon footprint of their kitchens: as much as 3,000 kg CO2-e – around the same as flying from London to Portugal and back or heating the average home for a year.

Forget the ‘fast kitchen’

In an industry deeply financially invested in the ‘fast-kitchen’ model and prone to greenwashing, HØLTE founders Fiona and Tom wanted to offer something else for their increasingly eco-conscious customers.

They liken the position of their industry to that of fashion a decade ago. Then, no one thought much about the environmental consequences of fast-fashion. Today, it’s a major influence on consumer decision-making. They hope that by acting now, they can spread consumer awareness and spur the wider kitchen industry to make a difference.

It’s time for carbon transparency

Height x width x depth… x CO2e

When planning a fitted kitchen, most of us think in three dimensions: height x width x depth. But there’s a fourth dimension that should be equally important: environmental impact.

Understanding the full extent of a products’ impact is a complex task – something out of reach for the vast majority of small businesses.

Danish carbon calculator, Målbar

HOLTE’s use the Danish carbon calculator, Målbar, which has already been used to great effect by the sustainability-driven furniture brand TAKT. Taking advantage of Målbar’s library of tools, HØLTE has spent 5 months generating a full set of hard CO2e data for every product in its range – and thus uncovering the full – and startling – environmental cost of a modern fitted kitchen.

A typical medium-sized kitchen from HØLTE generates 1,060kg CO2-e – a comparable figure to eight years of daily Starbucks, or a weekly steak habit for two years. This 1,060kg CO2-e total breaks down as follows:

| kg CO2-e | |

| Carbon storage | 84 |

| Materials | 386 |

| Surface treatment | 178 |

| Production | 113 |

| Packaging | 20 |

| Transport | 150 |

| Use (10 years) | 52 |

| Disposal | 244 |

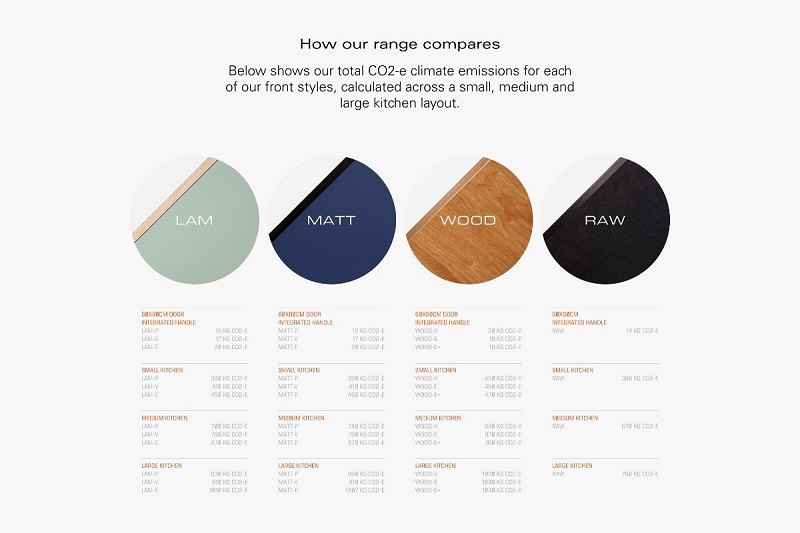

The figures represent an average, as the precise impact will depend on the specific products chosen – there is an emissions difference of around 40% between HØLTE’s worst-performing product and its best.

Fiona Ginnett, co-founder, HØLTE comments “The data was eye-opening. We had long been aware that the impact of our products on the environment must be significant, but our interaction with the C02-e emissions of products was limited as not many businesses have done it.

When we started calculating our products’ full-lifespan emissions it became clear that the impact of a whole kitchen is huge – a single cabinet door can generate the same emissions as 120 hours of Netflix or 92km in a car. It put a fire in our belly.”

And that’s just the start of it: this data includes only HØLTE-made components (door fronts, bespoke cabinetry and handles); once you include worktops and carcasses, the figure for a medium kitchen could potentially more than double to an estimated 2,500–3,000 kg CO2-e. Once the impact of kitchen appliances enters the equation, the statistics become astronomical.

Immediate change; long-term plans

In response to Målbar’s CO2e data, HØLTE has already overhauled a number of its practices and production methods to reduce emissions – and is looking for ways to do more. Some immediate changes include:

- switching from Formica to Arpa Bloom HPL which uses 50%-lignin resin;

- transitioning to using only water-based lacquers and paints;

- bringing the manufacture of components (such as handles) that were previously produced offshore in China back to the UK;

- and liaising with manufacturers to encourage more sustainable production practices and more efficient waste streams.

HØLTE is also using Målbar’s tools in its development process to ensure future products are as low-impact as possible, and to find ways of adapting existing products and materials.

Blame the Frankfurt kitchen

The reason for the magnitude of the modern kitchen’s emissions is, in large part, down to the rise of the ‘fast-kitchen’. Before the early 20th century, a kitchen was essentially a collection of standalone furniture – a range, a sink, a table and a dresser – which would likely be with you for a lifetime, moving from house to house, and, should anything cease to be functional, it could be replaced as a single piece.

Then in 1926, the arrival of the Frankfurt kitchen – designed for compact post-war housing – paved the way for the modern fitted kitchen, inseparable from the structural fabric of the home.

The convenience of the fitted kitchen has brought with it an enormous environmental compromise. Its panel-based construction and the material demands of fitted joinery necessitated energy-intensive production processes, generating extraordinary amounts of carbon. Today, even products made with ‘eco’ and recycled materials are still tremendously climate-damaging in emissions terms.

The energy demands of production, coupled with the ‘rip-out-and-replace’ mentality that we have collectively adopted, has meant that our kitchens are now among the biggest drivers of climate change in our homes.

The future is modular

These are all steps in the right direction, but they are small ones. HØLTE believes that ultimately, the only way to make the kitchen industry sustainable is if we ditch the ‘fast-kitchen’ model altogether, and in its place adopt an attitude to kitchens that prizes longevity, adaptability and environmental responsibility.

This will require a complete rethink of how kitchen cabinetry systems work, and is likely to involve both traditional materials – such as solid wood, a natural carbon store – and technical innovations such as injection-moulded recycled plastics.

HØLTE’S long-term vision is to develop a modular kitchen system that does not rely on heavily processed – and ultimately unsustainable – panel materials, but instead uses low-impact materials and processes. Such a system will be built to last, and will be able to move and adapt with its owner – rather than being ripped out, tipped and replaced as soon as someone new moves in.

“We want to encourage consumers to change their priorities and we want to challenge the industry – including ourselves – to make better and more accessible freestanding kitchens, to find new ways of doing things, to stop designing for obsolescence, and to develop kitchen systems that will last a lifetime.” concludes Fiona Ginnett, co-founder, HØLTE

Visit the HØLTE showroom at Unit G5 Northside Studios, 16–29 Andrews Road, London E8 4QF to find out more.